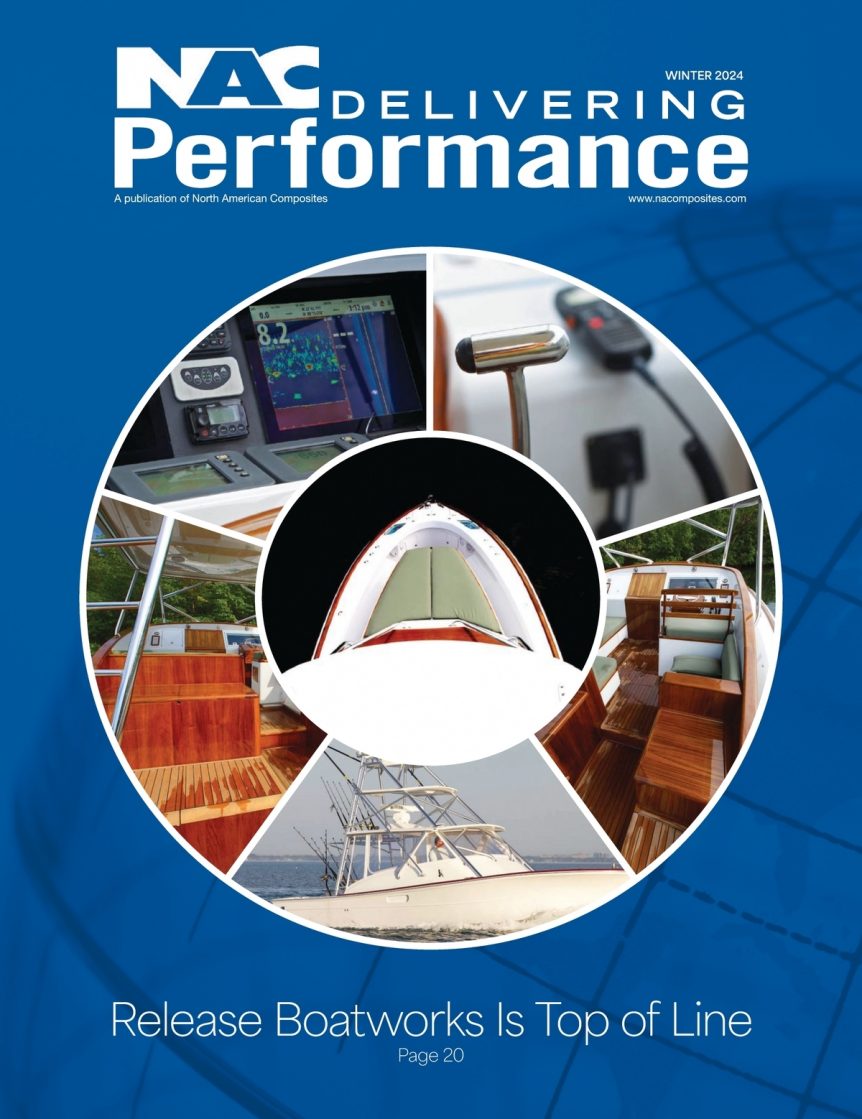

Release Boatworks Featured in North American Composites Magazine

This article originally appeared in the Winter 2023 issue of Delivering Performance, a publication of North American Composites.

by Reagan Cofield Diamond

Release Boatworks is where technology meets tradition. Founded in 2009 by owner Jim Turner, the company specializes in the building and production of myriad sport fishing, charter and custom boats. “I owned a resort in Guatemala,” said Turner, “and I had several classic, wooden custom Florida charter boats.” After restoring his eighth boat back to its original condition, a friend of Turner’s who assisted in the restoration process suggested that he design his own. “I thought that was a good idea,” said Turner, “and Release Boatworks was born.” He began building his first boat in Guatemala, but six months later realized that the country could not serve the company’s needs in the best way. Everything was shipped back to the United States and moved into a facility in Miami, Florida, for the first six or seven years of the company.

“I started the company there in the height of the recession — terrible time to start a boat company,” said Turner. “But everything went well, and sales were good. Eventually, we outgrew our whole facility there [in Miami] and had the opportunity to move everything into upstate New Jersey in Egg Harbor City.” Turner bought an old ocean yachts facility, and that is where Release Boatworks resides today. Recently, the company purchased a 43-acre waterfront property in Mays Landing, New Jersey, that will be utilized for launching and assembly. There is also a boatyard where service work will be done.

Sportfishing Yacht Model

One of Release Boatworks’s boats is the sportfishing yacht model. The bluefin tuna fish is credited with pushing the development of today’s sportfishing boats. Rather than purchasing a boat that was simply fast and nimble, traveling fishermen needed comfort for long distances. Enter Release Boatworks. The company’s boat designs are inspired by boats from the past, such as Whiticar, Rybovich and Merritt. “We have a classic look with a modern hull,” said Turner.

“We’re infusing the hulls and using the most advanced technology to build a product that looks like it could have been built 50 years ago. Hopefully, 50 years from now, it’ll still be a classic.”

When asked what separates Release Boatworks’s models from competitors, Turner explained that it’s becoming a harder question to answer. “When we started the company, from a technology standpoint, we felt that we were cutting-edge,” Turner said. “That’s where we want to be. With the advent of CNC Tooling and those kinds of things, boats that would have been considered in the middle of the market are so much better now.” With competition pushing the company to always improve, Turner holds a mantra for his company: “You don’t have to be different to be better. You have to be better to be different.”

Release Boatworks’s strategy to be better — and therefore different — is twofold. “People have a fast delivery time, and we’re a custom builder that builds at a production builder’s pace,” Turner explained. “By allowing customer input and customer-driven products, [combined with] a production builder’s timeframe and pricing — that’s our competitive advantage.” While the company’s direct competition might take two-plus years to build a boat order, Release Boatworks takes less than a year.

The NAC Relationship

Tom Henre became Release Boatworks’ contact at NAC four years ago. When the company began getting molds from Florida and started production, Henre gave suggestions on what to choose — leading to Release Boatworks choosing NAC as its supplier. The company uses a variety of composites — such as Marine MFG, Ineos resin, core materials, Airtech, and Axel releases — in its products. “I work closely with suppliers that I bring to Release to help them out and give them updated information of what’s going on in the industry,” said Henre. “As a result, we’ve gotten great success, and moving forward, [Release Boatworks is] actually going to start moving to an infusion process rather than hand layup and have Airtech and interplastic in place for that.”

“The most important aspect of our relationship with NAC is that they keep me abreast of the latest technology,” said Turner. “Staying cutting-edge is really our primary focus. We know where we want to get and, from a product standpoint, NAC helps us get there.” NAC keeps the company up to date on new technology

and information by getting updates from suppliers — such as emails on new product offerings — and Henre takes that information to the company via weekly phone calls. “I can use NAC to purchase directly from suppliers,” said Turner. “Because we’re a small company, we’re able to adapt to the latest and greatest techniques, products and materials — and NAC helps us facilitate that.” The relationship between Release Boatworks and NAC — and Turner and Henre — has launched what Henre calls “a really good business partnership.”

“We’re always communicating with each other, and I think it’s just going to keep growing from here,” Henre said. “It’s fun for me to watch them grow. To see how they’ve evolved over four years — right now, they’re sold out through 2025.”

Company Accomplishments

Over the past 15 years, Release Boatworks has faced many challenges — and come out on top each time. They’ve also been industry innovators. “Specifically, we build a lot of walkaround sport fishing and walk-around boats,” said Turner. “Up until Release, nobody was commercially successful in building that boat — a big version. So, I think that’s a big accomplishment.”

Moving the company — not across town, but from country to country — was another proud achievement. “Guatemala to Miami was about the same distance as moving from Miami to New Jersey,” said Turner. “Obviously, a little bit easier. By that time, there was a lot more tooling and molds and everything else. So, I think our biggest accomplishment is creating a niche market that didn’t exist before — and also surviving and thriving with all these major geographical moves.”

Learn more about North American Composites and read the full issue of Delivering Performance at www.nacomposites.com.